Abilities India Pistons & Rings Limited

Research and Development

Towards meeting the needs of new generation engines and products

Abilities India Pistons and Piston Rings Ltd. (AIP) has strategically established a Research & Development (R&D) Cell to cater to the present and future demands. This cell is focused on developing new materials, processes, techniques, and technologies to:

- Reduce weight and waste

- Enhance performance

- Adapt to evolving customer needs

- Stay updated with the latest technology through a policy of “Anticipatory Compliance”

Focus Areas in Research & Development

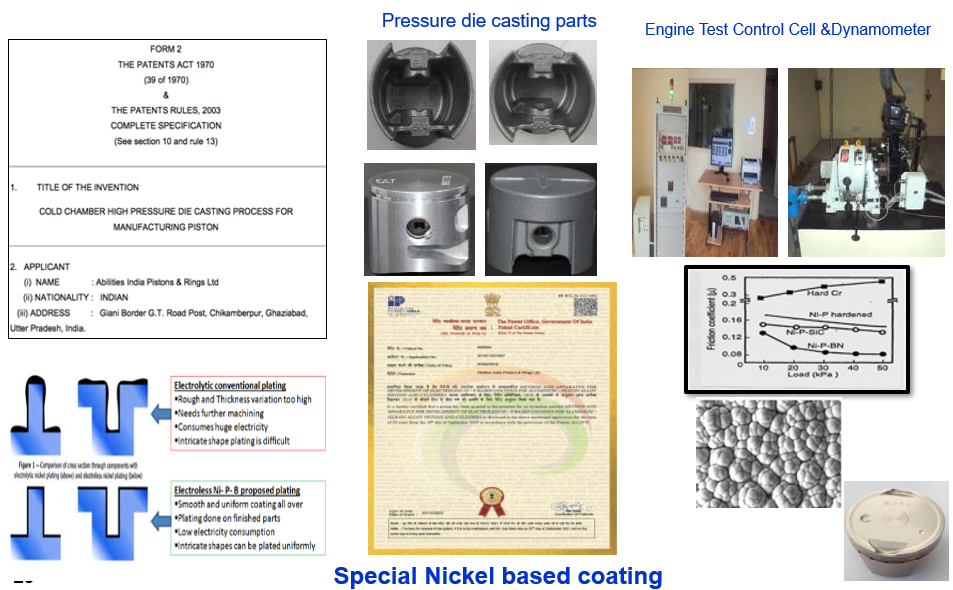

- Material Development: Exploring relationships between aluminum alloy composition, cast iron, and processing techniques to optimize microstructure and properties

- Low-Cost Defect-Free Casting: Developing casting processes tailored to specific requirements

Product Validation and Testing

AIP prioritizes product validation through performance and durability tests conducted with customer collaboration. Testing facilities are used to:

- Ensure compatibility with customer products like pistons, piston rings, cylinders, and die-cast items

- Set mutually agreed testing conditions to guarantee “trouble-free” products

- Build trust and confidence among discerning customers by meeting stringent quality standards

Innovative Product Development

The company continues to innovate by creating high-performance pressure and gravity castings that deliver:

- Superior thermal conductivity

- High strength for various applications, including railways, covers, and battery casings

Commitment to Excellence

AIP’s mission is to be the first choice for discerning customers. To achieve this:

- Prototypes are rigorously tested for design, physical, chemical, and metallurgical properties

- Durability is verified through engine testing facilities

Advanced Technologies

AIP leverages advanced software for:

- Foundry process simulations

- Product performance assessments before installation

- Detailed studies on piston and ring dynamics and boundary lubrication conditions

Sustainability and Future Goals

- Ethanol-Friendly Engines: Designing products compatible with ethanol

- Hydrogen Engines: Researching hydrogen engine technology

- Euro 6 Compliance: Developing engines that meet Euro 6 standards, with advancements in special alloys and coatings