Abilities India Pistons & Rings Limited

Manufacturing Philosophy

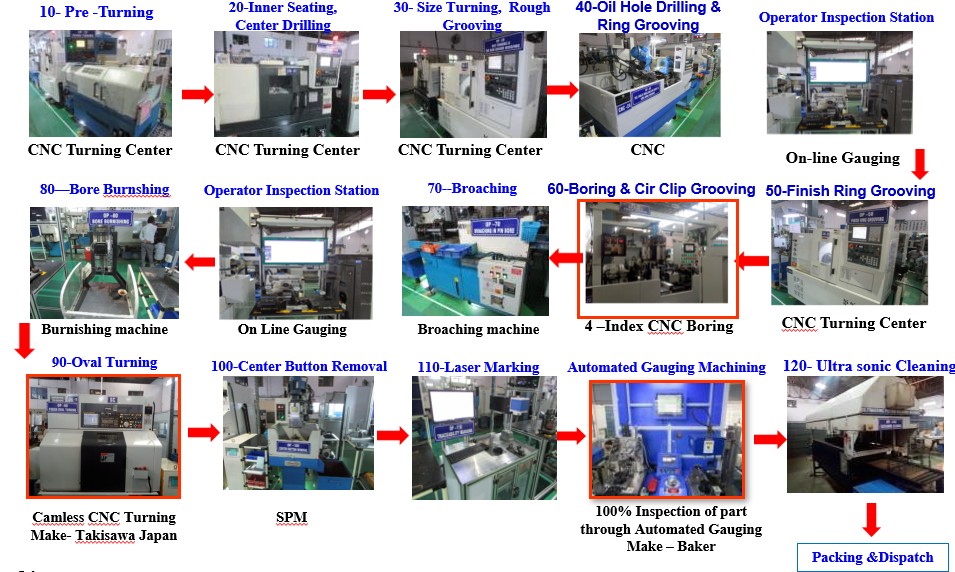

Flow diagram- Piston Machining

AIP uses the latest technology in both its manufacturing and testing philosophy. We use special-purpose PLC & CNC machinery and state-of-the-art computerized testing equipment.

Abilities focuses on both product repeatability and process repeatability. We incorporate Internet-of-Things (IoT) in every single stage of our manufacturing facility. This ensures process control for manufacturing within parameters, on-time inspection, and comprehensive traceability. We apply this philosophy across all our product lines: pistons (read here), piston rings, cylinders (read here), castings, and coatings.

Our facility is regularly updated to keep at par with global standards. This ensures that Abilities delivers the best to both its domestic and international customers. We have equipped our development department with 3D Computer Aided Design (CAD) for rapid development of new models for prompt delivery to our clients. Further, we have prismatic milling facilities for making dies at our CNC vertical machining centers from Mazak, Japan.

We believe in the principle of lean, not only in our manufacturing process but also in our equipment. As a result, we use peripheral devices to maintain quality at the highest standard and keep our costs competitive. This is accomplished through single-piece flow in all our manufacturing lines and active participation in cluster programs with other companies to achieve a common goal of zero effect & zero defect.

At AIP, we synthesize each product to meet high efficiency and environmental consideration, which translates to higher levels of precision and durability for our customers. Every product manufactured at AIP is at once traceable right from customer feedback, through production processes, to raw material and its source of supply.

Manufacturing Philosophy- Coating